Chapter 3Challenging Industry Norms

1950-1959

Starting Over

It was a certain day in 1951.

“What…?” the people in the room gasped as Eiichiro laid out a technical drawing on the desk in front of them. They peered at the drawing, but were at a loss for words. Nobody knew what to say next.

Not only did the drawing depict a large aircraft toy designed to an unprecedented scale, with a fuselage 37 centimeters in length and a wingspan of 39 centimeters from tip to tip, but it was also a replica of a U.S. B-29 Bomber, the very aircraft which had hastened Japan’s defeat in the war.

“The B-29 wreaked havoc on Japan during the war,” Eiichiro conceded, “but it is indeed regarded as the most distinguished airplane from America’s point of view. Given that, I want to make a product that will amaze children in America by showing them the truly remarkable technological capabilities of Japan’s toymakers.”

Everyone laughed at Eiichiro’s seemingly foolhardy idea as they curiously watched events unfold, particularly given that in those days toys were invariably small items that would fit in the palm of one’s hand. Still, Eiichiro along with his son Masanari, technology supervisor Kozaburo Kojima and others forged ahead through a process of trial and error in developing their B-29 toy, which would become the world’s largest friction toy at the time. The B-29 toy was priced at 500 yen and sold by Mitsukoshi department store in Nihonbashi, through Yonezawa Shokai. People in the industry were astonished by the success of the product as it practically flew off store shelves, selling out in just several hours despite what was then an extraordinarily high price of 500 yen in an era when a bowl of hot soba noodles in broth sold for only 15 yen

The popularity of the B-29 product extended beyond Japan after it was unveiled at a toy fair in New York the following year, to the amazement of buyers and winning their acclaim. The B-29 toy proved to be a huge hit and Eiichiro found himself with more orders than he could handle, even though the product was priced at five dollars in an era when most toys exported from Japan were available in the 50-cent to one dollar price range.

No sooner did he become filled with a renewed sense of determination, realizing that he belonged on the toy factory floor amid the hum of ketobashi foot press machines and the smell of grease rather than fishing on the banks of the Nakagawa river, than he suddenly found himself faced with an unexpected calamity after a short circuit triggered a fire at the Honden factory on a cold, snowy night in February 1952. The fire spread swiftly and the factory itself burnt to the ground, but crews were able to save metallic molds and presses for the B-29 product from the factory just in the nick of time. The disaster happened just as the entire workforce was gearing up with enthusiasm to begin mass production of the B-29 toy.

Eiichiro set out to visit Yonezawa Shokai first thing in the morning, leaving behind his stunned employees who were standing motionless, unable to set foot in the burnt-down factory as its still smoldering charred pillars remained hot even as dawn approached. Upon arrival, Eiichiro exchanged perfunctory greetings and then hastily reached into his inside pocket from which he produced blueprints for a new factory. Indeed, the timing alone seemed impeccable given that the factory had burnt to the ground just several hours earlier, but even more astonishing was the fact that the blueprints he furnished were for a new facility that was substantially larger than the one that had just been destroyed. Then president of Yonezawa Shokai, Yoshitaka Yonezawa, gazed at Eiichiro momentarily, but was at a loss for words. Then, with the factory blueprints before them, Eiichiro launched into his explanation. “I want to have an expansive factory built in large part so that we can embark on mass production of the B-29 toy,” he remarked before going on to say, “however, the problem is that we are short of funds, so would you be willing to lend us three million yen?” To that, Yonezawa, who was also a key player in the toy industry and really wanted Japanese toys to succeed in global markets, readily offered to lend Eiichiro the money.

The following day, President Yonezawa paid a visit to Eiichiro, with the three million yen he had promised to provide, neatly wrapped in a traditional Japanese-style furoshiki cloth and tucked under his arm. Clasping President Yonezawa’s hands, Eiichiro bowed and thanked him, and then looked him straight in the eyes and said, “by the way, would you be willing to accommodate us with an additional three million yen?”

President Yonezawa was speechless; all he could do was laugh.

So, drawing on the seed capital of six million yen, Eiichiro managed to have the large new factory far surpassing the former Honden factory built in just over a month, and at last launched mass production of the B-29 product.

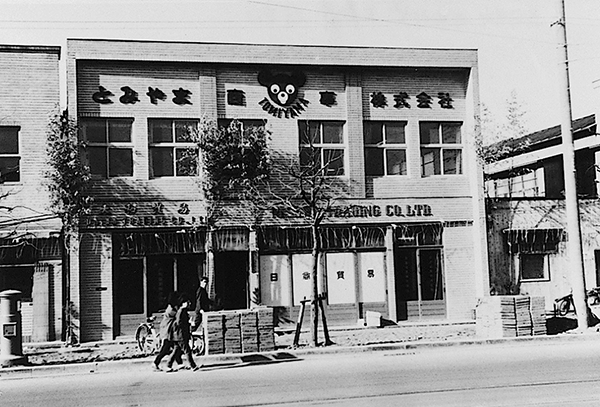

Operations of the new factory marked the beginnings of Tomiyama Toy Seisakusho, which would start out as Sanyo Toy Seisakusho.

Mistakes Revisited

The workforce of 60 employees on the payroll when the factory was restarted in March was increased to nearly 300 employees by 1953, in order to meet the huge influx of orders for the B-29 toy. With Yonezawa Shokai placing orders almost every day and factory machinery operating from morning to night, everyone was certain that the success would continue unabated. In the summer of 1953, however, the fateful day suddenly came when orders of the B-29 stalled.

With popularity of the product in America waning, Yonezawa Shokai requested substantial cuts in production, and consequently the factory which by then employed a workforce which had already swelled to 400 employees found itself in a predicament, meaning that Eiichiro would now be faced with an anguishing decision. Once again he would have to take painful action and scale back the workforce, as had been the case twice before, once during the Showa Depression and again during the Sino-Japanese War. Eiichiro just stood there ashamed of himself and sullenly biting his lip as he gazed at the red flag waving in the wind at the entrance to the factory gates.

On January 17, 1953, with the B-29 having become a hit product, Sanyo Toy Seisakusho was reorganized, and Sanyo Industry Company, Ltd. was established. The company would need to go head to head against competitors worldwide, and accordingly made drastic changes that involved shifting to a modern corporate structure and away from being an old-fashioned toy workshop that had been managed by a single supervisor.

To Eiichiro, who had built the company of his dreams, the business crisis sparked by the slowdown in demand for the B-29 toy made him realize the limitations faced by manufacturers that do not have a sales organization.

Operating a company whose business relied mainly on exports to the U.S., he had continued to make products at the behest of buyers, unaware of market trends. Such business practices ultimately resulted in a situation where the company was saddled with massive inventories and faced the prospect of having to reduce its workforce. As such, Eiichiro did some soul-searching in that regard, and in November 1955 sent his son Masanari along with Hiroshi Iwafune off to do research on the U.S. market. Hiroshi had been Masanari’s friend since junior high school, and worked at the company as a part-time translator.

For the first time in their lives, the two paid a visit to the U.S. to see things for themselves. While there, they enthusiastically bought up sample products, spending all the cash they had on hand, and even borrowed funds from importers. Through an introduction from the Japanese consulate, they were also given permission to tour factories of Mattel, which has long had a strong reputation as a top-notch toy manufacturer in the U.S., thereby enabling them to observe modern toy manufacturing processes in well-equipped facilities first-hand. After having witnessed the different practices of toymakers in the U.S., the two of them returned to Japan where they provided advice on building a factory equipped with state-of-the-art equipment. Before long, the company’s third factory was completed.

In those days, Eiichiro acted as chairman of the Tokyo Export Toy Manufacturers’ Cooperative Association and was devoting more and more of his time and energy to industry activities in that regard.

Japan’s Toy Industry Undergoes a Transformation

Japan’s 1956 economic white paper proudly declared that “the postwar era is over” in describing the underlying strengths of the nation which had undergone a dramatic resurgence in the years since its wartime defeat. The notion of “technological innovation” central to Japan’s progress also brought about substantial transformation with respect to the nation’s toy industry. For instance, innovation of materials and technologies was driving progress in terms of a shift from metal to plastic toys, and from friction-operated to electric toys. Eiichiro, who was in tune with the trends of the times, and also brimming with curiosity, had been instructing young team members to research new materials and technologies since the early postwar era, as he waited impatiently for the right opportunities to arise. Then, with completion of the third factory in 1956, he immediately initiated research into plastics. In 1957, he established a unit to handle designs involving plastic resins within the third factory, which culminated in full-scale use of plastics in manufacturing toys.

One product the company launched that was manufactured using such processes was its tinplate electric toy Bubble Blowing Elephant, which featured a cap that incorporated plastic materials. Because it used plastics which were new at the time and because it was a newly developed electric toy, not friction-powered, it was a big hit at the New York toy fair held in February 1957, and resulted in orders from Yonezawa Toys. The orders for the new product abruptly spurred the newly constructed third factory into action. Meanwhile, Eiichiro had learned a lesson from repeated experiences where he would continue to make products at the behest of wholesalers and accordingly hire more employees, only to ultimately end up in situations where he was left holding excess inventory and had to reduce the workforce. As a result, this time around he remained composed in providing his products to the market, taking a level-headed approach to production planning.

The notion that a company is supposed to take it upon itself to sell what it makes, which had historically been regarded as common practice in other industries, came to be seen as preposterous in the toy industry. Moreover, the manufacturing wholesalers at the time exerted control over the flow of capital and goods, extending from the planning phase to sales. As such, as far as they were concerned the notion that a manufacturer would take action in terms of creating a company to sell products was nothing short of shocking to those companies who felt that such a move would disrupt the industry.

Eiichiro listened to a proposal made by his son Masanari and Hiroshi Iwafune recommending that the company establish its own organizational structure for sales, and consequently he was profoundly moved knowing that the time had finally come for the company to take that course of action.

Once the decision had been made, the company moved swiftly. Eiichiro paid a visit to the man who had long been lending him support, President Yasuyoshi Yonezawa of Yonezawa Toys (formerly named Yonezawa Shokai), and enthusiastically conveyed his desire to establish a sales company. In reply, President Yonezawa conveyed his understanding and wished Eiichiro good luck.

On March 9, 1959, Tomiyama Shoji Trading Company, Ltd. was established, thereby fulfilling Eiichiro’s desire to form a sales company, which he had hoped to do since the company’s founding.

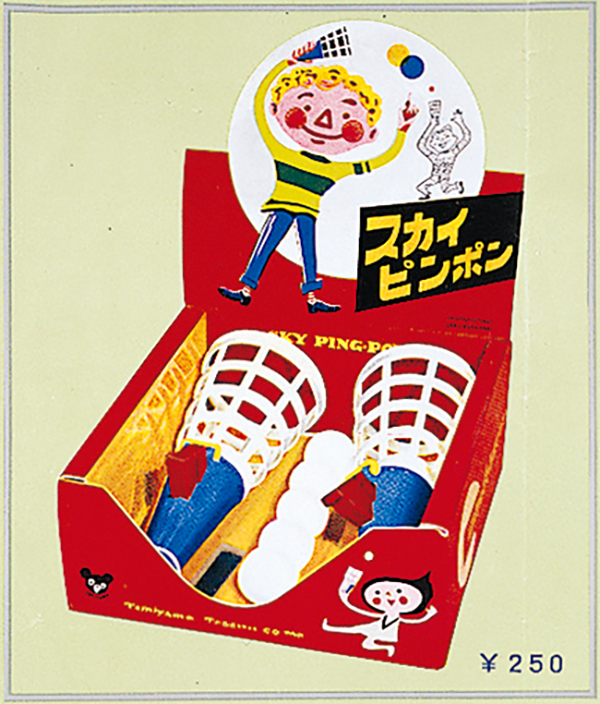

Eiichiro wanted the very first product handled as a sales company to be memorable in terms of it being groundbreaking and generating buzz. So, after a series of discussions, management decided on the Sky Ping-Pong product which would be the company’s first toy made entirely of plastic.

Releasing an all-plastic toy in an era of metal toys bolstered Tomiyama’s reputation as company that conceives innovative products. Developed drawing on sample products that Masanari and Hiroshi had gathered during their trip to observe the toy industry in the U.S., Sky Ping-Pong was a fun action game consisting of a spring-powered launching mechanism in a cone-shaped racket for playing catch with a ping-pong ball. One challenge in ensuring that the product would be a commercial success was that of addressing the high cost of durable materials needed for the flat spring used to launch ping-pong balls, particularly given that those springs tended to break easily. The company addressed the issue by designing it with replaceable springs and then including spare springs with the toy. As a result, the company was able to put the customer first by offering them a toy that was both reasonably-priced and durable.

Subsequently, Tomiyama Shoji’s entire workforce pulled together in efforts to promote sales of the product. For instance, the company launched an aggressive sales campaign that involved fitting the company’s cars with Sky Ping-Pong illustrations, paying for television advertising at a time when commercials for toys were uncommon, and posting hanging advertisements on Tokyo’s Yamanote train line. The company also attracted the attention of the industry by pursuing a series of new marketing strategies, which included holding events at retailers and running a promotional campaign involving complimentary flights for parents and their children in the skies above Tokyo in a DC-3 airplane which was an experience many longed for at the time.

Although the Sky Ping-Pong toy became a big hit for Tomiyama Shoji paving the way for vast opportunities, Eiichiro warned the company’s elated employees that markets are prone to change, and that the company’s next move would be important. He also asserted that a scenario of stagnant results always follows in the wake of a hit product, and that employees would need to maintain their focus in that regard.

Tomiyama Shoji’s challenge then became that of forging direct sales channels and moving away from its reliance thus far on manufacturing wholesalers with respect to sales in Japan, as well as with respect to its exports to overseas markets.

As the company was being established, managers actively engaged in business talks with key importers in the U.S., and successfully arranged export contracts the following year. During that phase of Tomiyama Shoji’s history, the company got off to a good start with achievements that included finalizing agreements for business with Sears, Roebuck and Co. which at the time was the largest mail-order merchandiser in the U.S. It would be safe to assume that success in this regard stemmed from positive name recognition of the Tomiyama brand as a Japanese toy manufacturer that had become known for its product development strengths and quality.

Moreover, the company’s business with Sears, Roebuck and Co. helped it subsequently gain trust and positive ratings among banks and other importers in the U.S. market.

At the same time the company was marketing the Sky Ping-Pong toy, the company’s development team was working on the Plastic Train and Rail Set which was the original PLARAIL railway toy which, even to this day, remains a favorite standby product. Upon looking at wooden railway train and tracks popular in Europe, Eiichiro said, “I bet it would be possible to make a plastic railway toy featuring various railway cars that would ride on rails,” and added “the use of plastics would enable us to create colorful designs.” Those words marked the beginning of the company’s line of plastic railway toys.

At first, Masanari and the development team created a set of eight curved rails that could be connected to form a ring and placed atop low Japanese-style chabudai tables which were common in Japanese homes at the time. They later came up with various products through a process of repeated trial and error where they would attempt different designs with respect to the shapes of rail connecting joints and railway cars that ran on the rails, and in 1959 the company released its hand-operated train set sold as the Plastic Train and Rail Set.

The railway toys became established in the market with the company’s release of its motorized Electric Pla-Train Set two years later.

The product development process entailed fervent efforts to modify and improve the toys so that they would be easier to play with and offer increasingly better quality. For instance, this involved considering various plastics and coming up with better rail shapes to address customer complaints that the rail connections tended to break easily.

In 1961, the railway toys suddenly gained much more exposure after being profiled as excellent toys in the popular Japanese magazine for housewives “Kurashi No Techo” (lifestyle notebook). Then in 1963, the railway sets established a position in the toy market under the name PLARAIL as a signature toy product line.

Later, the PLARAIL products became a huge hit in Japan amid growing popularity of trains fueled by the Hikari bullet train on the Tokaido line going into operation in conjunction with the Tokyo Olympic Games held the following year.