The TOMY Group is one hundred percent committed

to creating toys that children can enjoy playing with in absolute safety.

That means ensuring superior quality and safety across all points of

the toy-making process from planning and design through development,

retail and after-sales service. We have pursued superior quality and

safety tirelessly over our 90-year history.

Fostering a strong shared awareness of safety among Group employees,

encouraging tireless debate and checks in our factories,

proactively incorporating valuable customer feedback into future toy-making.

We believe that these are all vital elements for the consistentdevelopment of safe,

fun and attractive toys.

●The “Manufacturing”Value ChainCreating New Value through Play

The TOMY Group holds a Safety Day every year when all employees gather to consider the importance of safety and quality. Footage of the conference is made available to Group companies outside Japan as part of our drive to establish a strong collective awareness of safety across our global operations.

TOMY’s president appoints safety leaders annually. One safety leader is selected from each individual department including development, sales, quality assurance and customer services, and tasked with promoting safe toy manufacture over a one-year term. During that term, safety leaders meet regularly to discuss relevant customer feedback and quality-related developments in the toy industry, and report findings back to their individual departments.

The safety leaders meet regularly for Concentrated Play sessions. As the name suggests, these meetings enable groups of people to explore potential play options for a specific toy in depth. The leaders are on hand to ensure any safety or quality-related concerns are addressed. They verify a toy’s safety by predicting how a child might move and play with it: Could small children get their hand stuck in any part of the toy? Are there any small parts that a child might swallow? Does the toy contain any materials that might be dangerous if the toy breaks? Are the sound levels appropriate? Contributing their individual expertise to a concentrated debate, the safety leaders not only pinpoint and resolve issues, but enhance safety awareness across the TOMY Group.

Toys are a precious source of fun play for children, and, for that very reason, they must never cause injury or accident. The TOMY Group channels considerable resources and energy into creating toys for children to play safely and securely. We do that by systematically aligning the sequential toy-making stages from planning through to production under our own product safety and quality management rules, so we can actively preempt problems and offer greater toy security.

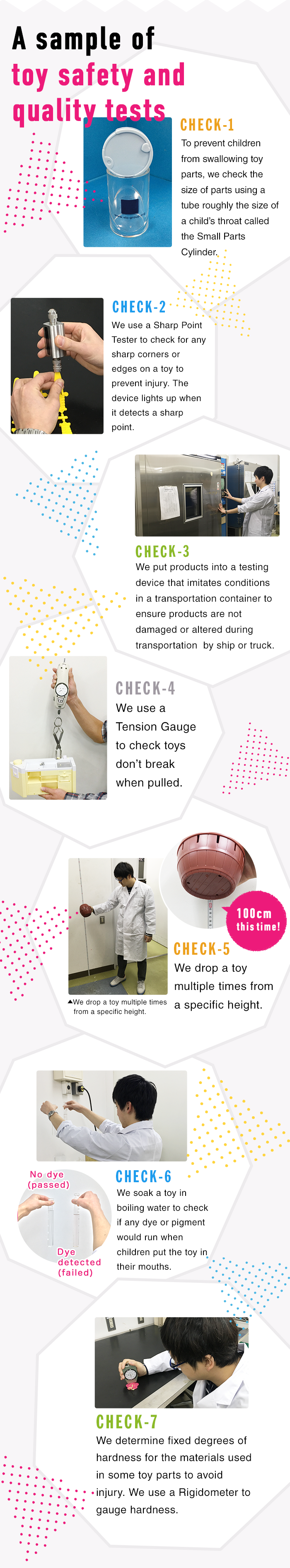

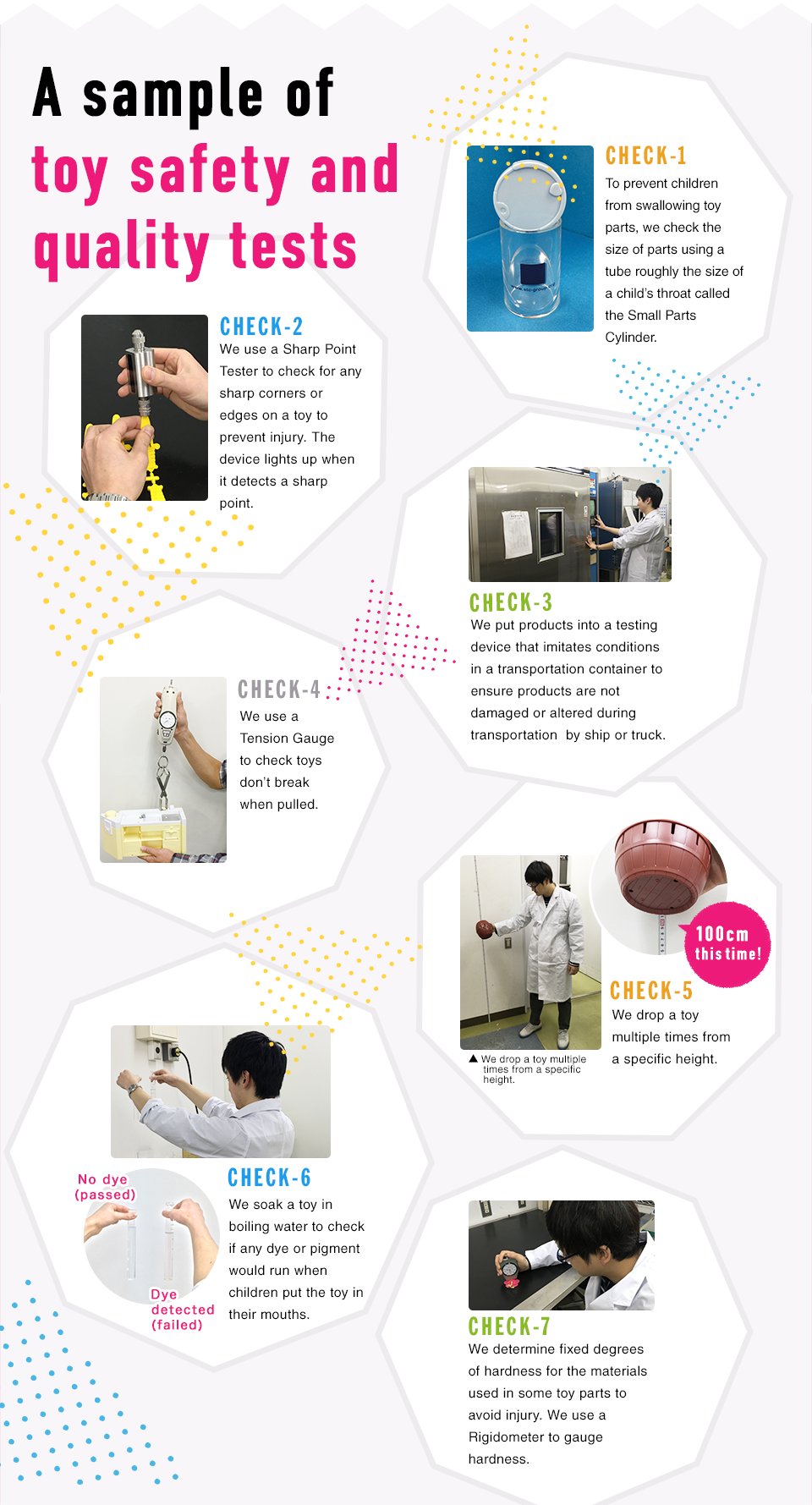

The toy industry has also developed safety standards. A toy must undergo rigorous testing by an independent specialist organization on shape, strength, flammability, and the presence of any harmful substances as stipulated under Japan’s Food Sanitation Act such as heavy metals or phthalic acid. The TOMY Group also tests toys against its own strict safety standards which are based on the Group’s toy-making expertise accumulated over its 90-year history, as well as industry-wide and country-specific safety regulations. We understand safety considerations will change as new forms of play emerge and technology evolves. That’s why we continually update our rules, standards and test parameters to suit changing times and ensure an optimum approach to toy safety.

The Safety Toy mark is displayed on toys that the industry recommends as having been carefully manufactured from a safety perspective

The Safety Toy mark is displayed on toys that the industry recommends as having been carefully manufactured from a safety perspective

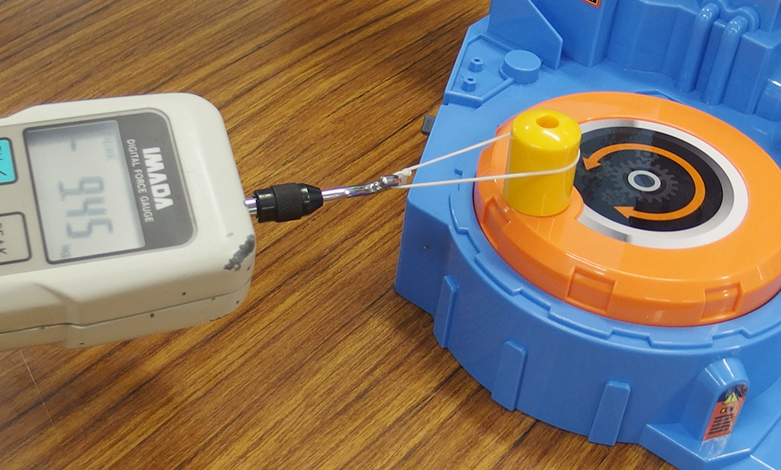

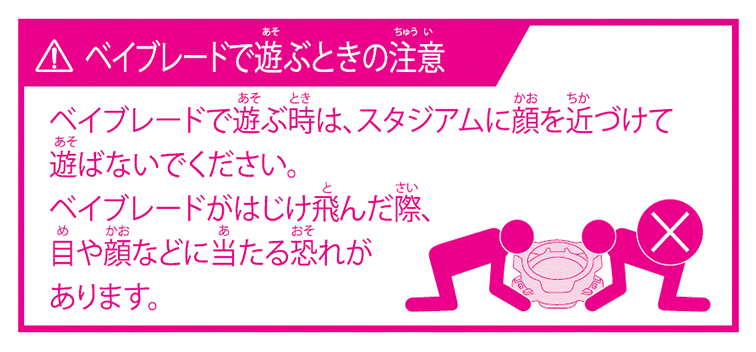

At the same time, it can be difficult to develop fun and exciting toys by focusing on safety alone. For example, to ensure children can play safely with our BEYBLADE BURST range without losing the fun burst feature, internal teams conduct multiple discussions and tests at every stage of the development process from planning, materials procurement, design and mockup, right through to the type of warnings included in the instruction manual or on the website.

To ensure safe play, we disclose safety advice and warnings to customers on the toy packaging and in the instruction manual, as well as on our website. We use pictographs* and other instantly understandable tools to indicate appropriate age range, warnings and cautions.

Our focus on safety continues even after toys have passed into the hands of customers.

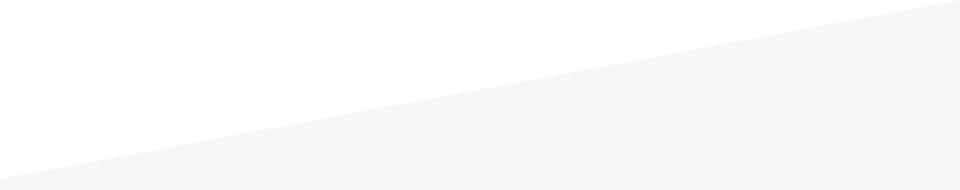

Our Customer Service Department responds to about 200,000 e-mail and telephone communications a year from customers seeking advice to offering feedback on specific toy products. To reflect customer feedback in future toy-making, we carefully record and analyze customer comments, identify problem causes and share results with relevant in-house departments.

We are especially attentive to customer concerns about potential injury or accident in relation to a specific toy. The Customer Service Department first ascertains whether a customer is injured or in danger, before conducting a detailed investigation of any near-miss incident in which a child is judged to have played with a toy in a completely unexpected way. The department shares its findings at safety leaders’ meetings or other venues to ensure any necessary measures are incorporated into future toy-manufacturing procedures.

Customer Support Puts Safety First

I am responsible for customer support across the TOMY Group and ensuring we make good use of valuable customer feedback. My daily work focuses primarily on safety, exploring customer reports to discover any possible danger or risk of injury. I work closely with the Safety and Quality Assurance Group to foster stronger understanding of safety within the Group, holding regular training and discussion sessions on reassurance of safety to improve customer satisfaction.

At the TOMY Group,

all employees from development

through customer services work

collectively to guarantee the

safety of our toys.

We are determined to further

improve product quality and

safety to

ensure we continue to

create toys children can enjoy

safely and securely

for many

generations to come.

The TOMY Group is passionate about delivering dreams for children.

For the very reason, it is important that we enjoy creating toys to bring joy to children

all over the world. We believe that building a comfortable working environment for employees is

essential to developing great toys. We work hard to provide solid employee-support systems

and foster a corporate climate conducive to enjoyable working environment.

I believe all TOMY Group employees share a common aspiration: To pursue dreams that are closest to children’s hearts whether their aim is to create toys, build new contents, improve their technical expertise, interact with children in toy stores and at events, or work in back-office departments to support colleagues. Instead of tailoring behavior to suit the company, I would like to see all employees enjoying their jobs, thinking and acting for themselves and challenging their limits as individuals. Especially I expect our younger employees to obtain a broader experience of life outside the company so they can introduce new ways of thinking that reject the commonplace and go beyond the obvious. I want to see them challenge and debate ideas with other team members, senior colleagues and management.

Pursuing an agile business model aligned with this rapidly changing society is vital to our future growth. Advancing our business model is bound to impact on work styles. When a broad-minded employee puts forward a determined proposal and sparks a lively debate, it is not just a potential business opportunity but a chance to improve internal systems, foster a more vibrant corporate climate and realize a more comfortable and creative TOMY-style working environment.

To encourage useful debate of new ideas, it is important to build mutual understanding and trust among employees. Our internal events provide an opportunity for them to get to know each other better. We seek to promote strong growth for the TOMY Group by urging employees and management to voice opinions honestly and earnestly, and encouraging every individual to act as a TOMY representative.

Children are our most important stakeholders. To help employees raise happy children, we have introduced systems to support employees to balance work and child-raising. Thanks to those systems, close on 100% of TOMY’s female employees take the childcare leave they are entitled to and close on 100% of those women subsequently reintegrate into the workplace.

New telecommuting system

TOMY began experimenting with employees working from home in 2010 before introducing a formal telecommuting system in 2014. Employees who would like to choose their work hours can work from home once a week to balance work and child or family care responsibilities. These employees can also take a break from their work to fulfill their care responsibilities such as dropping off and picking up children. Our employees appreciate this system because it allows them to work from home while caring for a child with an illness, alleviates their work commute and enables them to concentrate on their work.

Extended support before and after maternity leave

Another popular initiative is the extended support offered to female employees before going on maternity leave and after returning to work. Pregnant employees can use any expired paid leave to attend check-ups or hospital appointments or to take a break when not feeling well. They can also accumulate regular paid leave to cover any time they need to take off to care for sick children, etc. after returning to work. Since its introduction in 2007, many employees have used this system. We also have strong support mechanisms in place to help women reintegrate smoothly into the workplace. On returning to work, employees sit down with immediate superiors and staff from the personnel department to discuss the type of work they will do, the possibility of reduced work hours and whether they have a good support-system in place at home.

Other systems and initiatives to support employees balancing work with childcare and other family responsibilities

TOMY COMPANY

■Mental health counseling desks/ Pregnancy, childcare & health advice center

Two industrial counselors, one careers consultant and one health controller

■Childcare reduced work-hours program

Allows employees to shorten their working day by two hours until children reach elementary school age

■Flexible working program

Flexible work hours, discretionary work system

※TOMY Group companies also offer a variety of systems tailored to specific types of work and working arrangements.

We focus on creating the right environment and systems that enable our employees to work enthusiastically and create the toys of children’s dreams. With various new systems in place, TOMY Group employees don’t have to think twice about coming back to work after having children, and more returnees are opting to work reduced hours at the outset. As a manufacturer of toys, we seek to harness the valuable experience men and women gain from bringing up children, and that’s why we encourage male employees to take paternity leave and actively participate in childcare.

We believe employees who truly love their job can create great toys that make children smile all over the world. We have a project team, headed by our CEO, which plans a variety of internal events designed to make work more fun. The events provide opportunities for employees to interact more deeply, resulting in smoother communications and, ultimately, promoting the development of unique ideas and the creation of superior toys.

2016 company events

July

“Make Wishes Come True!” TOMY’s traditional Tanabata hanging of paper wishes on bamboo grass

August

“Beat the Heat!” Super Cool Biz by the CEO for the Day(famous kakigori shaved ice was served)

TOMY Group Family Day and CEO for the DaySeptember

“Get That Fall Feeling!” Enjoy tsukimi moon-viewing and moon-shaped rice dumplings

October

“Serious, Super Scary Disguise!” Halloween event in Tateishi, Katsushika

November

The “Get in Early!” Christmas support event with cake tasting and other activities

December

Celebrate 2016! The Game of Life with local gourmet

These company events boost communication between sections and departments that normally have little to do with each other. People get to do things at the company that they don’t normally experience in their daily lives. It’s a great way to help motivate people, especially the younger employees. TOMY is all about creating fun toys and experiences. That’s what makes these fun-filled events all the more special.

We hold a Family Day every August for employees to invite their families to the office. The event gives employees the chance to learn more about their colleagues’ personal lives and encourages mutual support in the workplace, contributing to a more family-oriented working climate.

Children experienced work life for a day, exchanging business cards and touring the office. They also enjoyed fun events such as street performances by popular staff. Elementary school children and older participated in practical sessions focusing on socially responsible toy-making initiatives related to safety, the environment and accessible design.

We held a tsukimi dango moon-shaped rice dumpling event in September to coincide with the traditional full-moon festival. We supplied 1,000 rice dumplings for employees who dropped into the conference room throughout the evening. We all got into the moon-viewing spirit by sampling local dango delights from five local stores in the neighborhood of our head office, including mugwort-flavored kusa dango, mitarashi dango with sweet soy sauce glaze, and fried dango.

October is all about Halloween. Everyone from the CEO down was allowed to come to work in Halloween costume. The company got behind the event by giving employees a financial allowance towards the costumes, and setting up a temporary zombie make-up booth staffed by professional makeup artists. Over 100 employees transformed themselves into an impressively unique range of zombies and ghosts. They took part in a parade with Katsushika’s mayor, district officials and residents, handing out toys to children along the route from the Keisei Tateishi Station past the TOMY head office to the Katsushika City Hall.

The TOMY Group is determined to furnish the right systems and foster good climate to create comfortable working environments for all employees to further improve our workplace

that creates the toys that children love.

If the global environment continues to deteriorate and

resources become increasingly scarce,

toy making may become a thing of the past.

This alarming prospect would have grim consequences

for both us as toymakers and the children who play with toys.

To help ensure children will still be able to play with toys one hundred years from now,

we have been actively promoting environmental awareness primarily through

Eco Toys based on our 100 Years to Play! concept.

We are determined to pursue a more sustainable society through

toy making and educational programs, together with children

who gain a greater awareness by playing with Eco Toys.

Have you ever seen an Eco Toy mark on the packaging?

The Eco Toy mark indicates toys that fulfill the TOMY Group’s environmental standards. The Group-wide Eco-Toy Committee sought independent advice to help determine eight specific Eco Toy standards. A toy that meets one or more of those criteria can display the Eco Toy mark on its packaging as an effective way of teaching customers about environment-conscious toy features.

Universal Design Initiatives through Accessible-Design Toys

In 1980, the TOMY Group started pioneering accessible-design toys that children with hearing or sight disabilities could also play with, and the concept soon spread across the industry. We use the Guide Dog mark on toy packaging for children with sight disabilities and the Rabbit mark for children with hearing difficulties. These marks are a great way of instantly highlighting a toy’s special features to consumers, as well as promoting understanding for children with disabilities.

Eco Toy initiatives to Help Build Eco-Awareness

Our Eco Toys were another industry-first initiative. Today, we continue to encourage green purchasing in the toy market by actively promoting the benefits of Eco Toys on our product packaging or through other means.

* Green purchasing refers to purchasing decisions that first consider carefully whether a product is needed or not, think about environmental factors as well as quality and price, and then select products and services that have the least impact on the environment from suppliers who make a conscious effort to reduce environmental impacts. (From the Green Purchasing Network website)* The Eco Toy mark is an example of Type 2 ISO environmental labeling which refers to self-declared environmental claims from manufacturers and businesses. The Japan Environment Association Eco Mark program is an example of Type 1 ISO environmental labeling with third-party certification.

PLARAIL: Lively announcements!

The E7 Series Shinkansen Kagayaki rail set with sound

Launched in April 2017, this product is an all-in-one set with PLARAIL train, rails and additional scene-setting pieces.

Our PLARAIL series has won the hearts of customers for over half a century now. Over the years, customers asked us to make the batteries last longer. That prompted us to develop a new sound chassis, including a small, lightweight motor designed exclusively for PLARAIL that uses less battery power and a new mechanism for efficiently transmitting power from the motor. As a result, the new train can run up to four times as long as previous model with less battery power. (Standard: Eco-friendly play: Energy conservation and reduction of waste)

We are working on reducing the environmental impact of our packaging by using eco-friendly printing ink made from vegetable oil. We are also trying to reduce packaging waste in the factory by using the paper scraps from package-cutting to create paper-craft accessories such as roadside trees that children can enjoy making up themselves.

PLARAIL is famous for its blue rails but we decided to change the color to green to instantly remind customers that the rails are made from recycled materials as the symbol of PLARAIL’s eco initiatives.

We launched the Eco Rails in 2012 after three years of research, development and adjustment to ensure uniform toy safety and color brilliance. In the same year, the products became the first toys to receive an Eco Mark certification from the Japan Environmental Association and won the Eco Mark Award 2012 Gold Prize. (Standard: Making eco-friendly toys: Using recycled materials)

▼For more details about the product, visit here. (In Japanese)

PLARAIL: Lively announcements! The E7 Series Shinkansen Kagayaki rail set with sound (In Japanese)

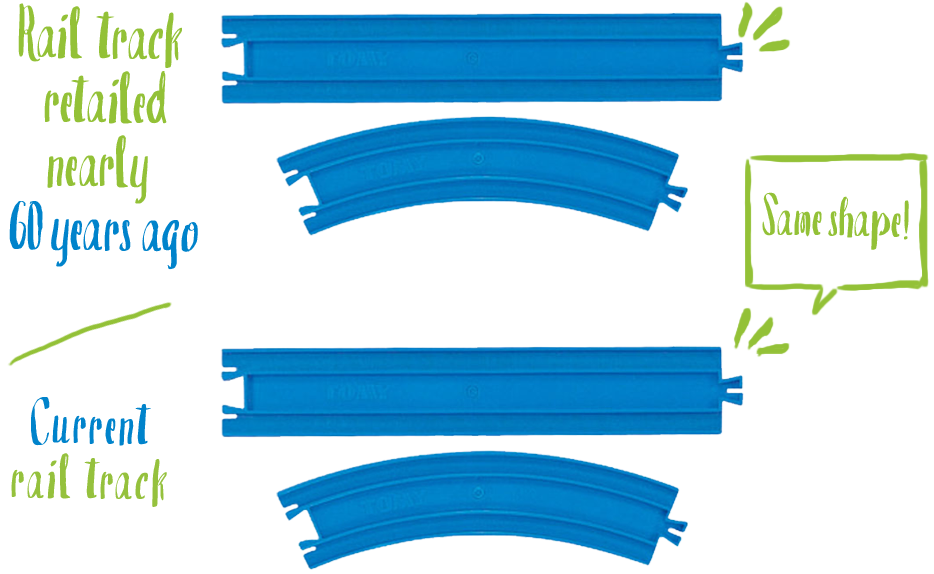

The E7 Series Shinkansen Kagayaki rail set with sound has incorporated such new environmental features, but PLARAIL has been promoting eco-friendly play ever since its first release in 1959. We have carefully maintained the original specifications, meaning you can link rail track retailed today with that retailed nearly 60 years ago! Take good care of your PLARAIL and children could get to play with their parent’s or even their grandparent’s rail track.

▼For more details about PLARAIL, visit here.

What is PLARAIL?

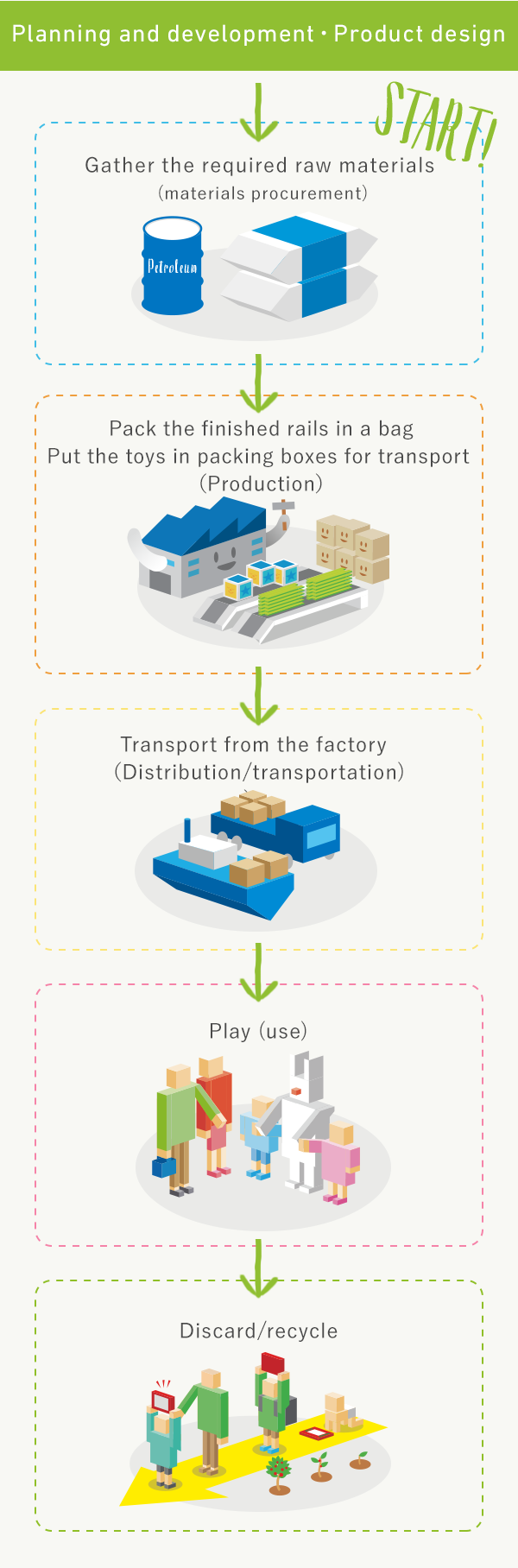

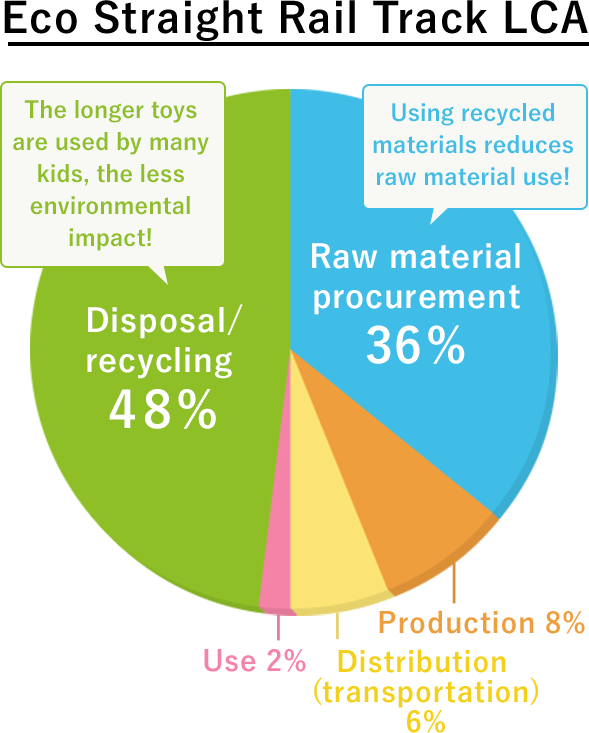

Using recycled materials and encouraging long-term use can bring various environmental benefits when you consider a toy’s entire life cycle from development to the point where a toy is no longer played with.

An analysis of the PLARAIL Eco Straight Rail’s life-cycle assessment (LCA)* data reveals significant CO2 emissions at the materials procurement and disposal stages. Based on that data, using recycled materials and maintaining the original specifications to promote long-term use constitute effective strategies from an LCA perspective as well. CO2 emissions from the Eco Straight Rails are approximately 10% lower than previous products. (LCA calculations conducted by Mizuho Information and Research Institute)

Since its launch in 1959, we have delivered about 98,700 km of PLARAIL rail track in total to customers. That’s equivalent to 2.5 times around the globe. We can generate more significant worthwhile benefits by introducing eco features into toys that many people have loved playing with for many years.

*A life-cycle assessment, or LCA, measures the environmental impact associated with all stages of a product’s life from raw material procurement, manufacturing and transport right through to final disposal.

We are keen to promote environmental awareness through toys, so we try to introduce many children to the concept of Eco Toys at green exhibitions and other events.

Back in December 2012, at the Eco-Product exhibition, an elementary school teacher told us of their desire to create some practical lesson plans on recycling using PLARAIL products. They asked if they could borrow some of the film roll and pellets used in making the toys. We were happy to help and were delighted to hear later how the materials had helped children grasp the fundamental ideas. We started to explore the potential benefits of using toys as teaching materials and decided to launch our educational support programs using Eco Toys.

We use PLARAIL rail track sets in our visiting lessons to illustrate our sustainable toy making. First we share information about how resource depletion and environmental problems are starting to impact toy manufacturing. If we can no longer make toys, then children will no longer be able to play with toys. Pointing out children this common threat for both the TOMY Group and children encourages them to think about the future of the earth and manufacturing. We also give them the chance to handle the plastic pellets and pieces of left-over food packaging from factories that are used as raw materials for Eco Rails, as well as some tools that children wouldn’t ordinarily get to see, such as toy development sketches, quality management rule books and safety testing tools. Such experiences are designed to spark children’s interest and understanding in toy making, recycling and green purchasing.

TOMY’s toy-focused educational programs have been widely recognized. Our visiting lesson program earned the Judge’s Commendation in 2015 and 2016 at the Award for Companies Promoting Experience-based Learning Activities for Youth hosted by Japan’s Ministry of Education, Culture, Sports, Science and Technology.

We will continue to enlist the help of children,

as future leaders, to progress our Eco Toy initiatives and ensure children

100 years from now can still experience the joy of toys.

Perfecting Product Quality Rules to Reflect Core TOMY Psyche

I am responsible for quality assurance across all product stages from planning and development through point of sale. I am also responsible for updating and revising our in-house product quality rules to enhance both the unique enjoyment of TOMY toys and the brand’s dedicated commitment to superior quality toy-making. In testing, we use TOMY’s own quality rules, which are stricter than the industry standards, and imagine how a child might use a toy so we can check its safety more accurately. Pulling this all together is a real challenge, but I feel people across the Group now understand the importance of timely revisions to quality rules. We adhere to these thorough safety management rules every day in our factories in the making of toys that children can really have fun playing with.